- Home Page

- Company Profile

-

Our Products

- Aluminum Collapsible Tube

- Aluminium Aerosol Cans Necking Machine

- Aluminum Laminated Cosmetic Empty Tubes Making Line 120TPM speed

- Filling And Sealing Machine

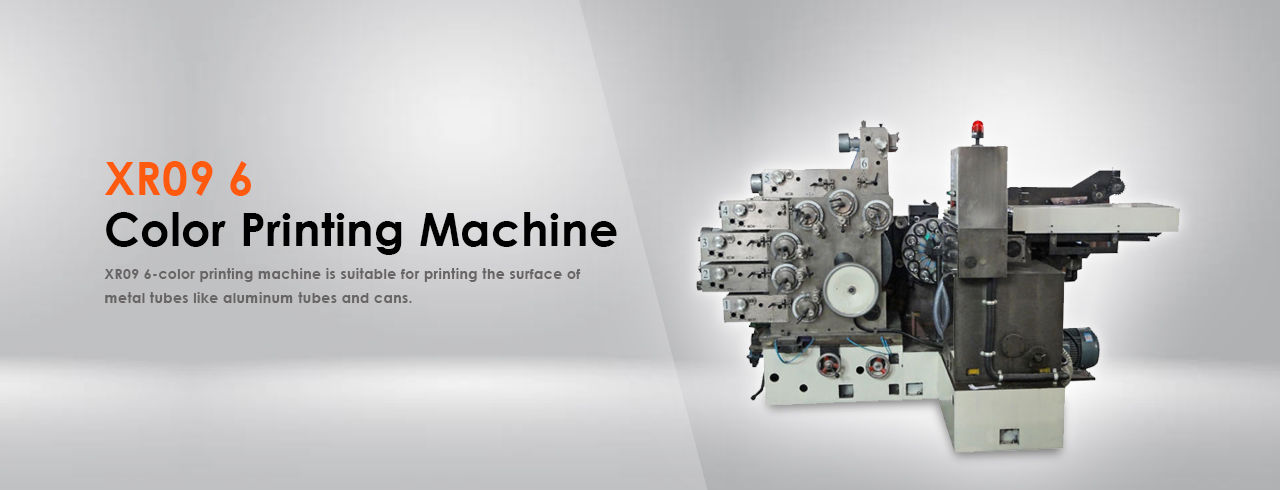

- Multi-color aluminum tube can printing machine

- Capping Machines

- HXG01 Drying Oven

- Annealing Oven For Aluminum Collapsible Tubes Making Line electric

- Slug Press Aluminum Ointment Tube Production Line Automatic chemical

- 6-Colors Offset Ink Printing Machine for Aluminum Cosmetic Tube Making Line

- PTD01 Internal Lacquering Machine for Aluminum Tube Line inner spray

- aluminum collapsible soft ointment tube making machine

- AUTOMATIC TUBE CAPPING MACHINE FOR COSMETICS TUBE IN COLLAPSIBLE ALUMINUM TUBE PRODUCTION LINE

- LATEXING MACHINE FOR SPRAYING GLUE ON IN THE TUBE IN THE ALUMINUM TUBE MAKING LINE

- Horizontal Extrusion Press Machine for Aluminium Collapsible Tubes Making Line

- Tube Printing Machine

- High Precision Internal Lacquering Machine for Collapsible Tube Making Line 60TPM Low Price

- Aluminum Shoe Polish Cream Empty Tubes Making Equipment Hand cream beauty

- Aluminum Cosmetic Squeeze Soft Tube Making Line Production machines hand cream 15g

- Annealing Oven for Aluminum Collapsible Tubes Making Line Electric Heating

- 6 COLOR PRINTING MACHINE FOR ALUMINUM MEDICINE TUBE IN ALUMINUM COLLAPSIBLE MACHINE LINE

- Slug Press Extruding Press Machine For Aluminum Tube Line Automatic

- Capping Machine for Aluminum Cosmetic Tube Making Line machines 100 or 60 speed

- Highly stable Drying Oven for aluminum collapsible tube production line

- Capping Machine for High Speed Aluminum Collapsible Tube Line 90-100

- High speed Latexing Machine For Cosmetic Tube Making Machine production line

- High Speed Collapsible Aluminum Soft Tubes Press Extrude Making Machine production line

- Aluminum Cosmetic Tubes Making Line Factory Manufacturer Full-Automatic production machine

- Collapsible Ointment Soft Tubes Production Line making machines

- NEW USED Aluminum Ointment Tube Production Line

- 100 Speed High Speed Capping Machine for Aluminum Tube Making Line NMG01

- whole word hot sale DYD01 base coating machine for cigar tube in aluminum collapsible tube production line

- 6-Colors Printing Machine for Aluminum Ointments Tubes Making Line

- Aluminum Collapsible Cosmetic Tube Production Making Line Automatic machines

- Aluminum Collapsible Cosmetic Tube Making Line Full-Automatic

- High Speed Aluminum Cosmetic Soft Tubes Making Machines

- High Speed Aluminum Cosmetic Tubes Production Line 10TPM

- Aluminum Cosmetic Tubes Production Line Making Machines High Speed 100TPM

- Aluminum Soft Glue Empty Tube Making Line Full-Automatic Slug Press

- Aluminum Super Glue Empty Tubes Slug Press Making Machines Production Line

- Aluminum Ointment Soft Tubes Production Line Machines COLLAPSIBLE tube making

- Aluminum Soft Tube Production Line Making Machines Fast Speed 120tpm Full-Automatic machine empty tubes

- Aluminum Cosmetic Collapsible Soft Empty Tube Making Machines Line Equipment turnkey project

- Slug Press Aluminum Cosmetic Tube Making Machines Line Collapsible Soft Empty

- Aluminium collapsible tubes production line 2023

- High Speed Aluminum Tube Production Line

- ointment aluminum tube equipment

- High Speed collapsible tubes cosmetics aluminum making machine

- High Speed Production Line for Aluminum aluminium cream glue Tubes

- High Speed Machine for Aluminum cream supper glue Tubes

- High Speed aluminium soft tubes line

- High Speed collapsible ointment tubes line

- High Speed Aluminium tube production line

- 6-color Printing Machine for aluminium collapsible tube

- Aluminum collapsible cosmetic tubes making machine

- High speed Aluminum cosmetic tube making machine

- High speed 150T Extrusion Press Machine for tube making machine

- LJG02-80 Extrusion Press Machine of High speed aluminium collapsible tube line

- aluminum cosmetic tube line

- Latexing Machine for aluminum tube cream tube

- Twist Capping Machine of High Speed Aluminium Collapsible Tube Line NMG01

- aluminum cosmetic tube making machine production line machines

- Latexing Machine for aluminium collapsible tube

- soft tube cosmetics packaging making machine

- YSG01 6-color Aluminum tubes printing machine

- Tubes Line for ointment

- Lacquering oven for the aluminum tube making machine

- aluminum tubes line

- aluminum tubes machine

- aluminum collapsible tubes making machine

- aluminum tubes printing machine

- Automatic Capping machine for aluminum collapsible tube product line

- Latexing machine for collapsible tube

- brush trimming machine for aluminium collapsible tube

- collapsible aluminum tubes production line

- Aluminum AB Glue Soft Tube Making Machines Line

- Automatic Packing Machine for Aluminum Soft Tube Making Machine Line BZD01

- Base Coating Machine for Aluminum Collapsible Tubes Making Line

- Cheap Price Aluminum Collapsible Tube Making Line High Speed

- Annealing Oven(Gas heating) for High Speed Aluminium Collapsible Tubes Making Line THD electric

- BEST PRICE EXTRUSION PRESS MACHINE IN COLLAPSIBLE TUBE LRPDUCTION LINE FOR ALUMINUM GLUE TUBE

- New type and low price offset printing machine

- stable and best price base coating machine for collapsible tube of aluminum tube line equipment

- High speed aluminum metal collapsible tube production line

- Aluminum Aerosol Can Production Line

- Aluminum Rigid Cans production line

- Aluminum Cans production equipment

- Aluminum Fire Extinguisher Cans production line

- Aluminium Aerosol spray aerosol can dome making machine

- aluminum deodorant can equipment

- Machine of Aluminum Fire Extinguisher Cans

- aluminum spray cans making line

- aluminum canister making line

- aluminum perfume can line

- aluminum rigid-wall can line

- Aluminum Rigid Cans Line

- Aluminum can production line

- aluminum perfume can production line

- automatic aluminum cans line

- production line for deodorant cans

- Aluminum Aerosol Can Manufacturing linemachine

- Equipment of Aluminum Hard Cans Production Line

- Trimming cum brushing Machine for aluminum cans production line

- Lacquer curing oven(Gas) for beverage can making machine

- Aluminum beverage can production line

- LJC01 Extrusion Press Machine for tube can cans making production line 80T

- QXC02 Can Washing Machine for aluminum can making line Spray Type Production empty aerosol cans

- Lacquer Curing Oven For Aluminum Can Making Line GHC01 aerosol can production

- Aluminum aerosol cans production line for 2020

- Aluminium Can AL Mono block Cans whole Production Line Manufacturer

- High quality and speed aluminium can making machine

- 6-colors printing machine for aluminum aerosol spray cans production line

- Competitive price Aluminum can making machine for aerosol cans

- Necking Machine for aluminum aerosol can production line

- Washing machine for aerosol spray can making machine

- Production Line of Aluminum Aerosol Spray Can Making Machines MACHINE equipment manufacturer

- aluminum monobloc aerosol can line

- Monobloc Aluminum can making machines

- New Washing Machine for aluminum aerosol spray cans production line

- Washing Machine (Spray Type) of Aluminum Aerosol Spray Can Production Line Making Machines deodorant

- Base-coating Machine for aluminum aerosol spray cans production line

- monoblock aluminium packaging can making machines turnkey lines machine

- 6 colors Printing Machine of Aluminum Can Aerosol Spray Cans Production Line Making machines YSC01 six color

- Electric Magnetic Shell Production Line

- Trimming machine cutting machine for Cylindrical Battery case Shell

- Extrusion press machine for Cylindrical Battery case Shell

- Hot sale Cylindrical Battery case Shell making machines

- Lithium ion Cylindrical Battery case Shell making machines Extrusion press machine

- LJC extrusion press machine for Lithium ion Cylindrical Battery Shell

- Spare Parts

- 2023 High quality customized spray gun for internal coating machine

- High quality customized hardened belleville spring disc

- Disc spring spare parts for Extrusion press machine

- Gripper for tube making machine

- Spray gun spare parts for Latex machine for aluminum tube machine

- Spray gun spare parts for Internal printing machine for aluminum tube machine

- Flat belt spare parts for Conveyor shaft for aluminum tube machine

- Spray Guns for Internal Coating Spraying Machine Aluminum Tube High quality customized soft tubes

- Gripper for printing machine Base coating machine aluminum tube line Retainer manipulator

- Flat belt for Conveyor shaft for aluminum tube machines machine

- High Quality Spring Leaf Customized Hardened Extrusion Press Machine Discs slug press

- Mandrel Specifications Cylinder Dabber Spare Parts

- Chains chain Spare Parts for Aluminum Tube Making Machine

- Capping Bowl Spare Parts for Capping Machine for Aluminum Tube Making machine

- High quality Spray gun spare parts for Internal printing machine for aluminum tube machine

- Economic Spray gun spare parts for Internal printing machine for aluminum tube machine

- Competitive Price Spray gun spare parts for Internal printing machine for aluminum tube machine

- High quality Spray gun spare parts for Latex machine for aluminum tube machine

- Economic Spray gun spare parts for Latex machine for aluminum tube machine

- clamp hand spare parts for aluminum tube machine

- Gripper for printing machine aluminum tube machine

- Spray gun for Internal printing machine

- Airbrush for Internal printing machine

- Airbrush spare parts for Internal printing machine for aluminum tube machine

- Airbrush spare parts for Latex machine for aluminum tube machine

- clamp hand spare part

- Manipulators spare parts

- Robotic spare parts for aluminum tube machine

- Gripper of printing machine for aluminum tube

- Clamp hand for base printing machine aluminum tube machine

- Raw Materials

- Toothpaste line

- Tube Filling And Sealing Machine

- filling and sealing machine

- GZ05C Automatic Colorful Toothpaste Filling and Sealing Machine

- FULL AUTOMATIC HIGH SPEED BOXING MACHINE FOR TOOTHPASTE TUBE IN TOOTHPASTE MAKING LINE

- Full Automatic Thermal Shrink Film Packaging Machine toothpaste plastic container

- Toothpaste Making Line

- GZ06 Automatic Filling and Sealing Machine aluminum tube making

- ABLPBL Tube

- 6-Color Offset Printing Machine For Plastic Tube

- Automatic Laminated Tube Making Machine for chemical tubes in packing machine line

- AutomatiC shoulder making machines for Round and Oval Shoulder in the laminated tube production line

- Aluminum-Plastic Laminated Tube Making Machine

- Abl And Pbl Laminated Tube Making Machine

- maquina offset de 6 colores

- 4 6 colors offset printing machine for plastic cosmetic tube

- aluminium beverage can printing machine 6 colors

- Factory price hot air tube ABL Laminated Tube Making Machine

- High quality for ABL PBL toothpaste Laminated Tube Making Machines

- Plastic PE Tube extruder Making Machine

- 5 layer soft Tube extruder Machine

- 6 color Plastic soft tube Printing machine

- 8 color Printing machine for Plastic cosmetic tube

- capping and sealing machine for Plastic cosmetic tube

- 2 layer Plastic PE soft Tube extruder Machine for cosmetic packaging

- Plastic PE cosmetic tube extruder machine

- Cosmetic Tube Extruding Machine Hotel Tube Extruding Machine

- Multilayer Cosmetic PE Tube Extrusion Machine

- UV bulbs for printing machine

- aluminum foil for printing machine

- UV bulbs for offset printing machine

- aluminum foil for offset 6 color printing machine

- Ungrouped

- Automatic lacquer curing oven in aluminum tube making line GHD01

- Latexing machine for aluminum collapsible tube line

- New Capper machine for aluminum tubes

- Cost-effective 6-Color Printing Machine for aluminum collapsible tube line

- Newest 5-Color Printing Machine for Aluminum Collapsible Tubes Making Line

- High quality Latexing Machine for aluminum tubes

- High speed Aluminum Aerosol can production line

- New automatic Base coating Machine

- Lacquer Curing Oven for mental tube packaging

- Price competitive Aluminum tubes production line

- 6-color Aluminum Aerosol Cans Printing Machine Full-Automatic colors

- 6-color Printing Machine for Aluminium Monoblock aerosol Can Making Machine

- Drying Oven Gas for Aluminum Aerosol Cans Making Line electric

- High quality Aluminum bottle Can Making Machine Production Line cans empty

- Aluminum Slug Press Aerosol Cans Making Line Machines

- Aluminum Monoblock Fire Extinguisher Empty Body Cans Production Line

- offset printing machine for cream ointment tube

- JA88-800 Horizontal cold extrusion press

- Aluminum Collapsible Tube

- Certificates

- Infrastructure

- Contact Us

Need support or do you want to any

work with us.

Need support or do you want to any

work with us.

Send Inquiry

Send Inquiry Send SMS

Send SMS